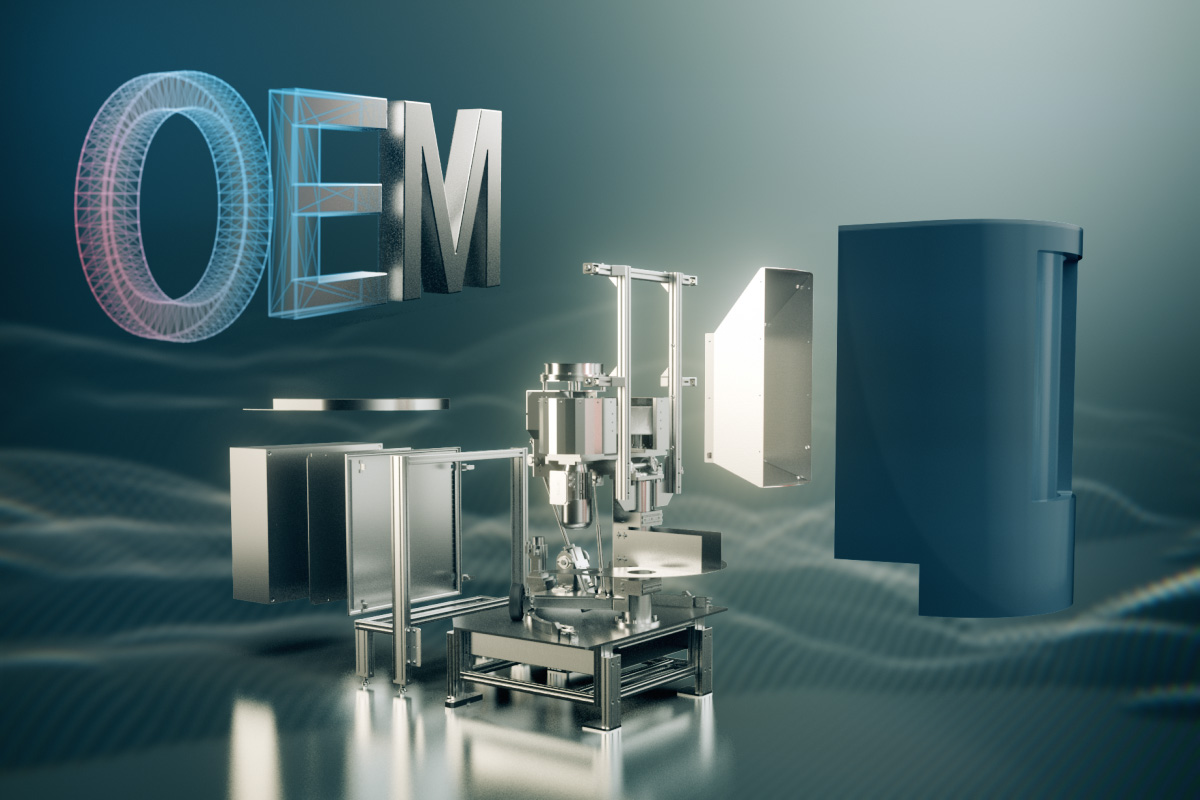

OEM production

Your focus is entirely on research and product development. You outsource manufacturing and assembly. As a system supplier, we cover the entire manufacturing process and, in addition to production, also handle the purchase of components for you.

Our OEM services range from engineering, manufacturing, assembly and functional testing to product documentation and shipping. Whether for global corporations, medium-sized companies or small businesses, Anton Paar ShapeTec manufactures OEM products of the highest quality in any quantity.

With us, your ideas take shape.

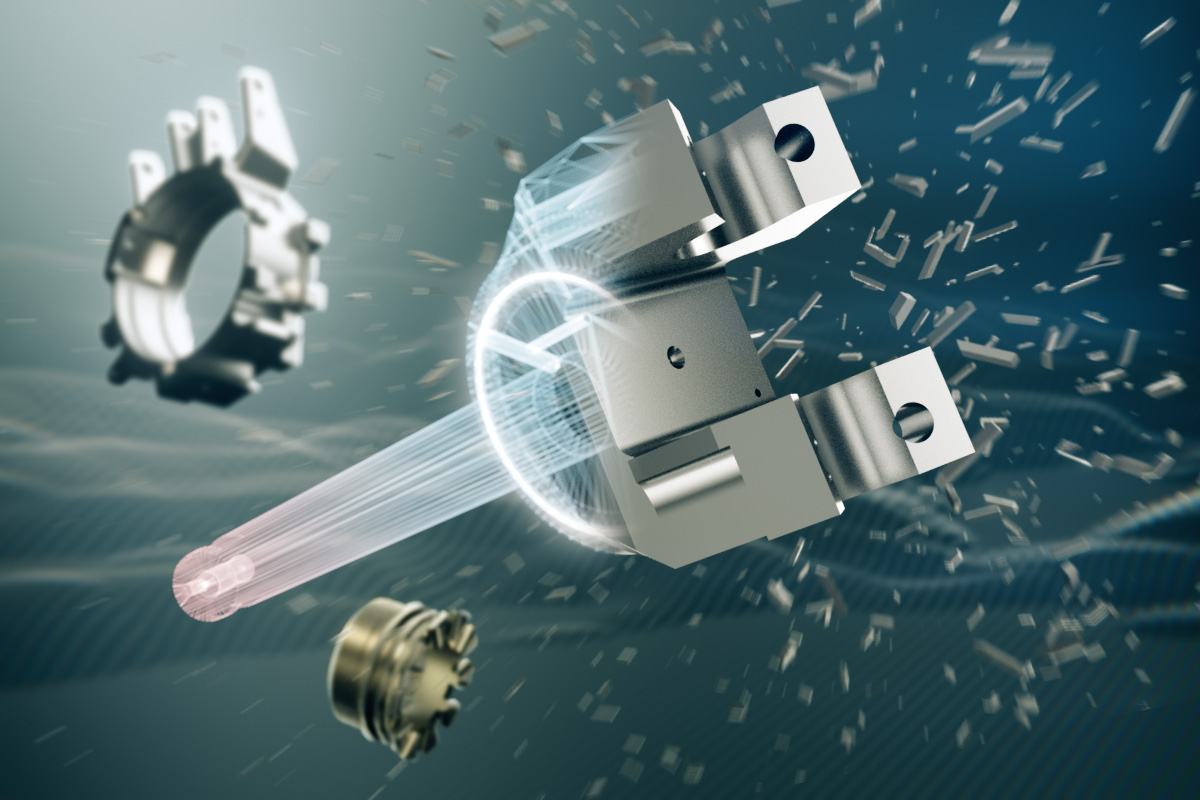

Component production

At our four locations in Europe, we produce individual parts and components as well as ready-to-install assemblies for well-known companies in the medical technology, aviation and railway technology sectors. From chassis components and components for prostheses, to emergency call columns.

Complex, safety-critical components with high load limits require absolute manufacturing precision. That's why we rely on a wide range of technologies in non-cutting and cutting production, joining technology and surface finishing.

We are your partner for complex geometries with tolerances down to 1 micrometer.

Casing construction

The housing of your products embodies your brand and the value of your product in a unique way. Whether information terminals, laboratory measuring devices, industrial monitors, control cabinets, loudspeaker housings or fire alarm systems:

We manufacture housings of all kinds in various shapes and sizes up to protection class IP69, EMC-compliant or EX-protected. Depending on the application of the enclosure, we carefully select the materials with you. And in production, we rely on all technologies of sheet metal processing, machining and surface technology.

Realize your ideas with us in terms of form, function and design.

Electronics manufacturing

Electronic components are always part of a larger whole. As an EMS service provider, we offer you comprehensive services for the production of prototypes and series: Printed circuit board assembly using the most modern SHT and THT processes, as well as cable assembly. We support you by means of DfM services to exploit improvement potentials at an early stage, and to avoid costly adjustments in series production.

Extensive test procedures such as AOI, Quins, in-circuit tests and flying probe test systems guarantee the highest quality and maximum functional reliability of all electronic components.

We know how to produce efficiently and at fair prices at our Austrian location using the most modern technologies.