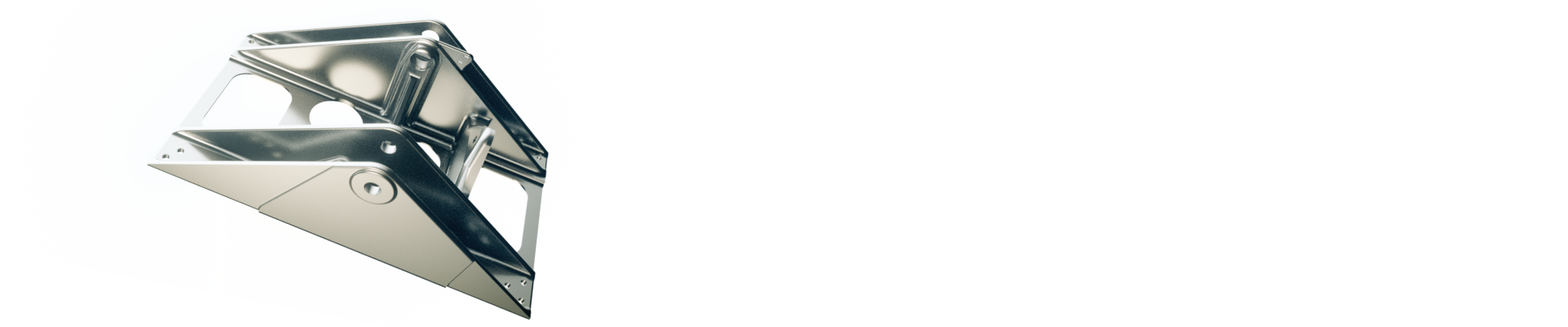

High temperature differences. Corrosion. Violent shaking. Extreme material loads in aviation demand material and manufacturing know-how at the highest level. From landing gear components to emergency exit hammers. As a supplier to the aviation industry, we manufacture a wide range of high-precision, ready-to-install components for sports and training aircraft, as well as for civil aviation.

Special surface finish. For perfect corrosion protection.

To survive in a highly corrosive environment, the perfect surface finish is just as important as the molding itself. It's not uncommon for aerospace components to undergo four to five surface finishing steps at our facility: Blasting; chromic acid anodizing; chemical oxidation; primer coating; painting.

We offer all surface technologies directly in our company, or we work closely with renowned partners. Benefit from our wide range of surface processing services at economically attractive conditions.

Welding. According to aviation standard ISO 24394.

Weld seams in aviation have to withstand the highest loads. Anton Paar ShapeTec is a certified company for welding according to aerospace standard DIN ISO 24394. We pay particular attention to the process reliability of our welding procedures, and also carry out weld seam tests in accordance with EN9712. All components manufactured in our company meet aviation specifications and safety concepts 100%.

Competences

Any questions? Contact us!