Increasingly complex geometries. Smaller, smarter and more functional parts. Modern medical technology manufacturers rightly expect uncompromising quality from their partners in the supply chain. We supply companies in this highly sensitive industry with components for prostheses, implants, system components and devices for navigated surgery as well as containers for surgical instruments. Perfection begins in the production of precise parts. And ends with a successful result in the surgical environment. We are your manufacturing partner when perfection in every production step and tolerances down to the micrometer range are required.

Risk classes. Compliance requirements met.

The manufacture of every single part in medical technology is subject to a highly regulated environment and the strictest manufacturing and quality controls. As a certified company according to ISO 13485, we support you with our know-how and expertise. And meet compliance requirements 100 %. We work with the greatest care and consistency throughout all production steps and manufacture components up to the highest risk class III. It goes without saying that every production step in our company is traceable and fully documented.

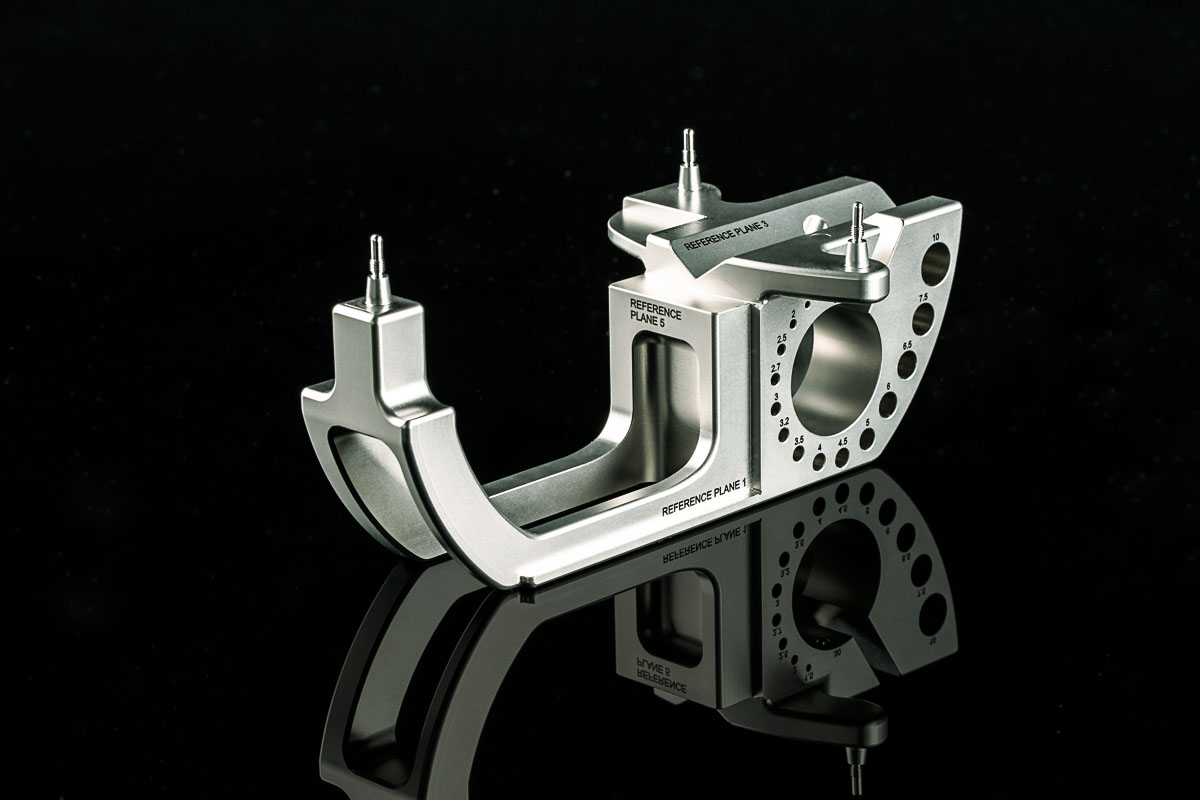

High precision in the µ-range. For maximum surface quality.

We produce precision components with complex geometries and minimal wall thicknesses, from titanium, aluminium and various stainless steel alloys to non-ferrous metals and plastics. To this end, we rely on the latest CNC machining centres, which enable us to produce parts with the lowest form and position tolerances in just one clamping, as well as on specialist personnel with relevant experience. In the machining area we can achieve tolerances of less than 1 µm. To deliver the optimum surface finish, we use a wide range of surface finishing techniques such as electropolishing, vibratory grinding, blasting, anodizing, and flow deburring. We either rely on our own long-standing expertise or work closely with renowned partners. Mechanical dimensional checks as well as manual inspections and final batch releases guarantee a consistently high product quality, from initial sampling to series production. Because when it comes to a person's life, there can be no compromises.

Competences

Any questions? Contact us!